There are 6 specific reasons why 430 stainless steel pipe is not easy to weld:

1. High thermal conductivity: 430 stainless steel pipes have higher thermal conductivity compared to austenitic stainless steel. This means that they can dissipate heat more effectively, and maintaining the heat required for welding can be challenging.

2. Rapid cooling rate: 430 stainless steel pipes tend to experience rapid cooling rates during welding, especially in thicker sections. This rapid cooling can cause brittle phases such as martensite to form in the heat-affected zone, increasing the risk of cracking.

3. Sensitivity to hydrogen embrittlement: Ferritic stainless steel is more susceptible to hydrogen embrittlement during welding. The welding process introduces hydrogen into the material, which can cause the formation of hydrogen-induced cracks if not managed properly.

4. Sensitivity to hot cracking: 430 ferritic stainless steel is prone to hot cracking, especially in the presence of impurities such as sulfur and phosphorus. The welding process may introduce these impurities, and proper welding techniques (such as preheating and controlling the interlayer temperature) are essential to minimize the risk of hot cracking.

5. Limited ductility at low temperatures: 430 stainless steel exhibits reduced ductility at lower temperatures, and the welding process involves localized heating and cooling. Such temperature fluctuations can cause embrittlement of the weld joint and reduce toughness.

6. Chromium carbide formation: Ferritic stainless steels may be prone to the formation of chromium carbides at grain boundaries, especially when the carbon content is high. This can lead to sensitization of the heat-affected zone and reduced corrosion resistance.

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593

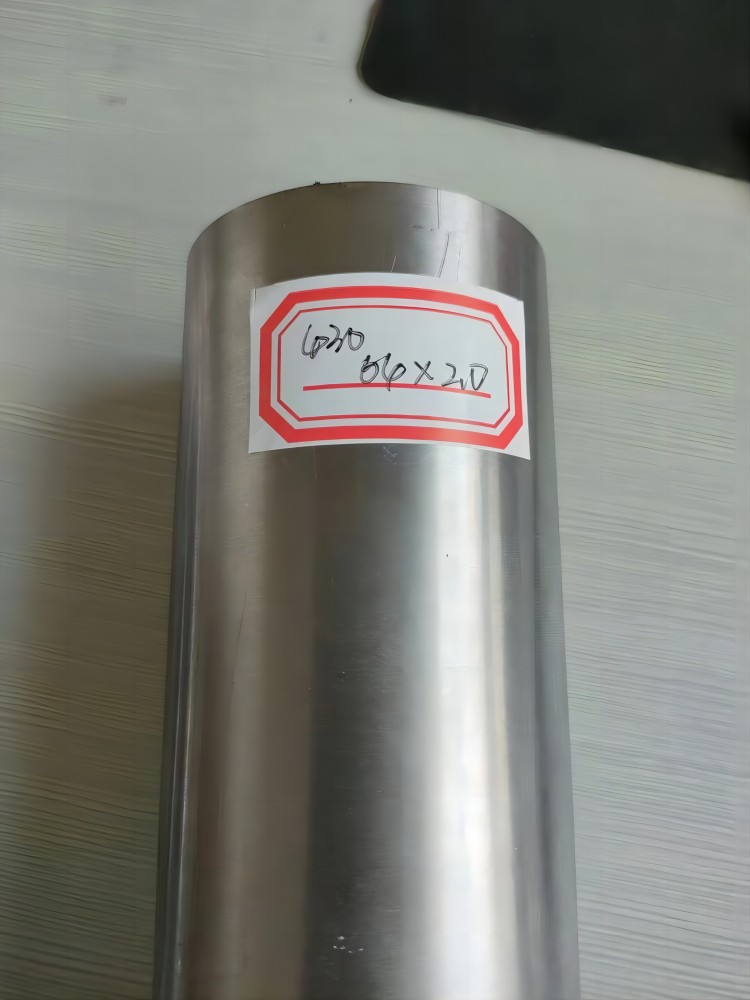

#sspipe #sstube #weldedpipe #430pipe #430tube