Beginning in World War II, “superalloys” were first used to describe a group of alloys developed in turbochargers and aircraft turbine engines that required high performance at high temperatures. The application range of superalloys has expanded to many other fields, including aircraft and land-based gas turbines, rocket engines, chemical and petroleum plants.

They are especially suitable for these demanding applications. Superalloys are based on Group VIIIB elements and generally consist of various combinations of Fe, Ni, Co, and Cr with small amounts of W, Mo, Ta, Nb, Ti, and Al. The three main superalloys are nickel, iron, and cobalt-based alloys.

Like iron and copper, nickel has been used in alloys since it entered civil society. But compared to steel, brass and bronze, nickel alloys are latecomers to the chemical industry. The development of nickel alloys has been promoted by the continuous advancement of metallurgical technology and manufacturing technology, which has promoted its wide application in the chemical industry. Nickel alloys have excellent corrosion resistance, strength, toughness, metallurgical stability, processability and weldability. Many nickel alloys also have excellent heat resistance, making them ideal for applications requiring high-temperature strength and high-temperature chemical resistance.

The first commercially important nickel alloy was Alloy 400, which was developed in 1905 by the International Nickel Corporation (later known as Inco Alloys) and sold under the trademark MONEL. The next important milestones were nickel-molybdenum alloy B and nickel-chromium-molybdenum-tungsten alloy C, which were introduced around 1930. Their inventor was Haynes Stellite (now Haynes International), and two of them are registered under the trademark HASTELLOY.

The next important stage in the development of nickel-based alloys came from Inco, which developed Inconel 600 in 1931 and nickel-iron-chromium alloys in 1949, named INCONEL and INCOLOY. Inco and Haynes capitalized on the initial popularity and reputation of these marks to introduce about 50 corrosion and heat resistant alloys in the MONEL, INCONEL, INCOLOY and HASTELLOY series. VDM was later a well-known developer and producer of nickel-based alloys with the trademarks Nicrofer, Nimofer and Nicorros.

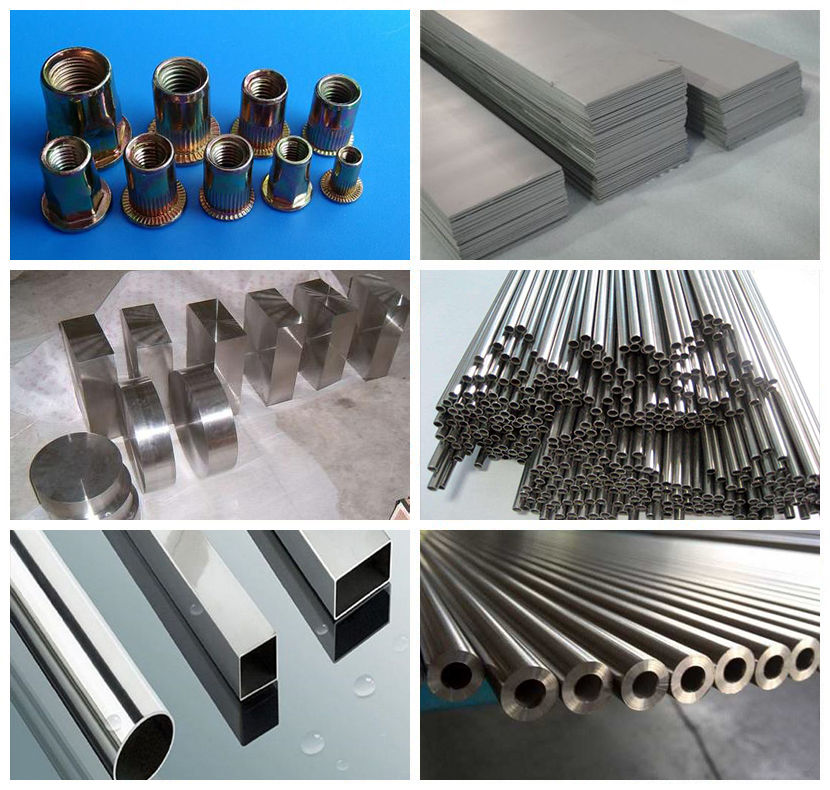

SHAANXI JINYOU METAL TECHNOLOGY CO., LTD Mainly engaged in alloy steel, 3-series stainless steel, 4-series stainless steel, nickel-based alloys, high-temperature alloys, Hastelloy alloys, duplex steels, European standard steel plates, Kovar alloys, tungsten steel and other products. A metal steel group integrating production, processing, sales, and trade, and has its own processing and cutting service department, providing sheet cross-cutting, longitudinal shearing, laser cutting, water jet cutting, pipe fittings (tees, elbows, etc.) Production, welded pipe processing, flange fastener processing, explosive composite plate, bar forging and other one-stop processing supporting services.