Stainless steel coloring methods are as follows:

⑴ chemical oxidation coloring method;

(2) Electrochemical oxidation coloring method;

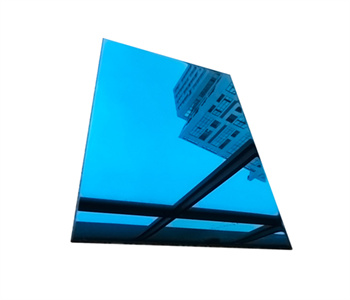

(3) Ion deposition oxide coloring method;

⑷ high temperature oxidation coloring method;

⑸ gas-phase cracking coloring method.

A brief overview of the various methods is as follows:

(1) Chemical oxidation coloring method: It is the color of the film formed by chemical oxidation in a specific solution, including dichromate method, mixed sodium salt method, vulcanization method, acid oxidation method and alkaline oxidation method. Generally, “INCO” (INCO) is used more, but if you want to ensure the same color and luster of a batch of products, you must use a reference electrode to control.

(2) Electrochemical coloring method: It is the color of the film formed by electrochemical oxidation in a specific solution.

(3) Ion deposition oxide coloring method chemical method: the stainless steel workpiece is placed in a vacuum coating machine for vacuum evaporation plating. For example: titanium-plated watch cases and watch straps are generally golden yellow. This method is suitable for high-volume stainless steel machining. Because of the large investment and high cost, small batch products are not cost-effective.

⑷ High temperature oxidation coloring method: In a specific molten salt, the workpiece is immersed in a certain process parameter, so that the workpiece forms a certain thickness of oxide film, and presents various colors.

⑸ Gas-phase cracking coloring method: It is more complicated and less used in industry.