Due to the characteristics of stainless steel and the special requirements for product quality, the stainless steel cold rolling production process has the following characteristics:

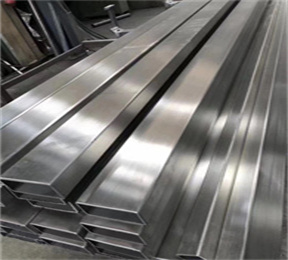

(1) Stainless steel is a kind of high alloy steel, which has a large resistance to rolling deformation. In order to carry out high-efficiency and high-precision rolling, a rolling mill with high rigidity should be used, and a multi-roll cold rolling mill is generally used.

(2) The multi-roll cold rolling mill generally adopts the single-machine reversible rolling method. The head and tail parts wound on the coiler during rolling are not rolled and are cut off to become waste. In order to improve the yield of the product, a section of lead strip should be welded at both ends of the stainless steel strip before rolling, and the lead strip part should not be rolled; in addition, if the quality of the hot-rolled coil is too small, in order to improve the rolling efficiency and yield; The small steel coils are pre-welded into large steel coils; in the continuous annealing and pickling unit, because of the continuous operation, the head and tail connections of the steel strips also need to be welded.

(3) Before the cold rolling of the stainless steel strip, the raw material (hot-rolled coil) should be annealed, and the intermediate annealing should be done during the cold rolling process. There are many kinds of stainless steel, the properties of various steels are different, and the purposes, methods and requirements of heat treatment are different, and there is a unique process system.

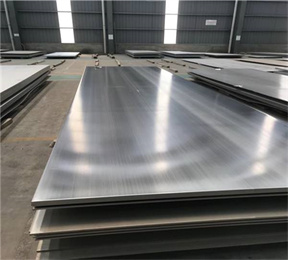

(4) The requirements for the surface quality of cold-rolled stainless steel strip are very strict, not only the metallurgical defects and processing defects caused by the previous process are not allowed to remain, but also the obvious defects caused by the cold-rolling process are not allowed. To this end, a series of elimination and protection measures have been taken in the cold rolling production process.

(5) There are some special requirements for the finishing of stainless steel strips. For example, the flattening process should not only improve the shape of the plate, but also use rolls with very low roughness (except for the hemp panel) to produce bright 2B steel plates. For ferritic stainless steel, the formability of the steel plate should be improved by controlling the amount of flattening. Because stainless steel is hard; at the same time, it has strict requirements on straightness, so it must be straightened with a strong straightening machine, and products with different thicknesses often need different straightening methods; Therefore, the modern stainless steel cold rolling plant is equipped with a slitting unit and a cross-cutting unit respectively.