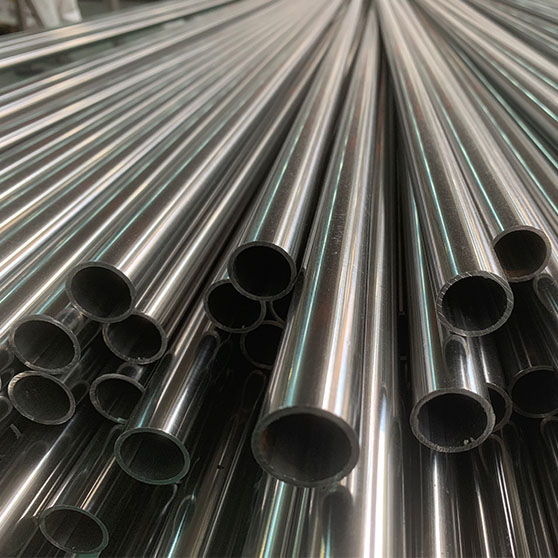

Precision stainless steel pipe is a kind of high-precision steel pipe material that has been processed by cold drawing or hot rolling. During the production process, precision pipes are not only in terms of the smoothness of the appearance, the cleanliness of the inner wall, but also the thickness and outer diameter of the precision pipe. The tolerance range is much stricter than that of ordinary stainless steel pipes. Maybe some customers require that the inner hole of precision pipes must be polished. Let me explain to you how to polish the inner hole of precision stainless steel pipes?

Inner hole polishing is a professional term for mechanical processing, also called deep hole polishing. The inner hole polishing of precision stainless steel pipes is a processing method that reduces the roughness of the inner hole through mechanical, electric spark, electrochemical, plasma, honing machine polishing and other polishing methods. Use mechanical, chemical or electrochemical effects to reduce the roughness of the inner surface of the tube to obtain a bright and smooth processing method. The following introduces two polishing methods commonly used for polishing the inner hole of precision stainless steel pipes.

1. Electrochemical polishing

Internal hole polishing usually uses electrochemical polishing because of its high production efficiency, low cost, and increased corrosion resistance of the tube surface. However, for other small-diameter precision stainless steel pipes, most of them use mechanical methods, which are difficult to polish the inner hole, difficult to inspect, and time-consuming. The inner hole is processed by electric spark discharge, which has high machining accuracy and good finish, but it is time-consuming. Through effective means, various internal hole polishing, deburring and mirror polishing problems can be solved.

2. Quilting machine polishing

Of course, you can also use a quilting machine to polish the inner hole of the precision stainless steel round tube, or you can use a vertical drill (if the hole is not too deep) or a radial drill for quilting and grinding. Quilting is performed by using a quilting grinding head. The structure of the quilting grinding head is cylindrical. There are several grooves around the circumference for installing oilstone strips, and compression springs are installed on the bottom of the grooves. During quilting, the compression spring pushes the oil stone to the inner wall of the round tube, and a quilting grinder drives the tool bar of the quilting grinding head to rotate up and down to polish the inner wall of the tube. Generally speaking, the stroke of a quilting grinder is much larger than that of a vertical drill or radial drill. The quilting grinder can be used to process relatively long precision stainless steel pipes. Vertical drills or radial drills can only process relatively short pipes. The accuracy of quilting can reach less than 0.01mm. Chemical polishing can only polish those pipes with inherently smooth inner walls, but is not suitable for pipes with poor inner wall roughness.

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593

#stainlesssteelpipe #stainlesssteeltube #seamlesspipe #201pipe #304pipe #316pipe #pipefactory #pipemanufacture #polishpipe #Mirrorpipe #tubequality #stainlesssteelpipe #stainlesssteelpipes #stainlesssteelpipesupplier #stainlesssteelpipefactory #StainlessSteelPipeManufacturer #stainlesssteeltube #stainlesssteeltubes #stainlesssteeltubesupplier #stainlesssteeltubefactory #stainlesssteeltubemanufacturer