The differences and uses of stainless steel 2D surfaces and 2B surfaces can be briefly summarized from the following two blocks:

1. Introduction to the differences between stainless steel 2D surface and 2B surface:

Many customers still don’t quite understand the difference between the 2D surface and the 2B surface of stainless steel. Here is a brief introduction:

NO.1 Silvery white, matte. A rough, matte surface that is hot-rolled to a specified thickness and then annealed and descaled. Uses that do not require surface gloss.

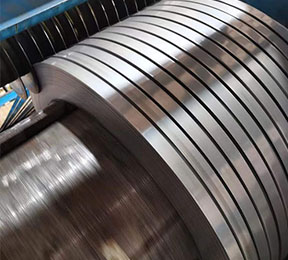

NO. Stainless steel 2D surface, silver-white cold rolling, heat treatment and pickling, sometimes a final light rolling on the rough side roller, a matte surface processing 2D product used for purposes that do not have strict surface requirements, general materials, Deep drawing materials.

NO. The surface gloss of stainless steel 2B is stronger than that of stainless steel 2D. After surface treatment of stainless steel 2D, it is subjected to a final light cold rolling with a polishing roller to obtain appropriate gloss. This is the most commonly used surface treatment and can also be used as the first step in polishing. The 2D surface of general stainless steel is also one of the common stainless steel cold-rolled surfaces. However, there are currently not many cold-rolled stainless steels with 2D stainless steel surfaces on the market, so many people do not know much about 2D stainless steel surfaces. In fact, 2D stainless steel surfaces are widely used in some industries.

2. Introduction to the uses of stainless steel 2D surface and 2B surface:

The characteristics of the 2D surface of stainless steel are widely used in the following two aspects: one is workpieces that require deep drawing. The rough surface of the workpiece itself facilitates retaining lubricant on the surface of the steel plate during deep drawing, improving the quality of deep drawing processing. However, if the workpiece has requirements for surface brightness, stainless steel polishing will be required after forming. The second is some workpieces that need to be sprayed, because the adhesion of the coating on the rough surface is much better than that on the 2B surface. This is widely used in container manufacturing. Currently, in the container manufacturing industry, 304 and 304L stainless steel on the 2D surface are very popular. Wide range of applications. Compared with the common 2B surface, the 2D surface is less smooth than the 2B surface, but the overall surface is still very uniform and matte. The 2D surface is generally heat treated and pickled after cold rolling, and then smoothed with a matte roller.

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593

#stainlesssteelsheet #2dsheet #2bsheet #2dcoil #2bcoil #2dplate #2bplate #sssheet #sscoil #ssplate