Thickness: 0.1 mm-250 mm

Width: 50 mm-3500 mm

Material: 2205, 2507, 2304, S32205, S32304, S32750, etc

Standard: AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc

Certification: ISO SGS BV

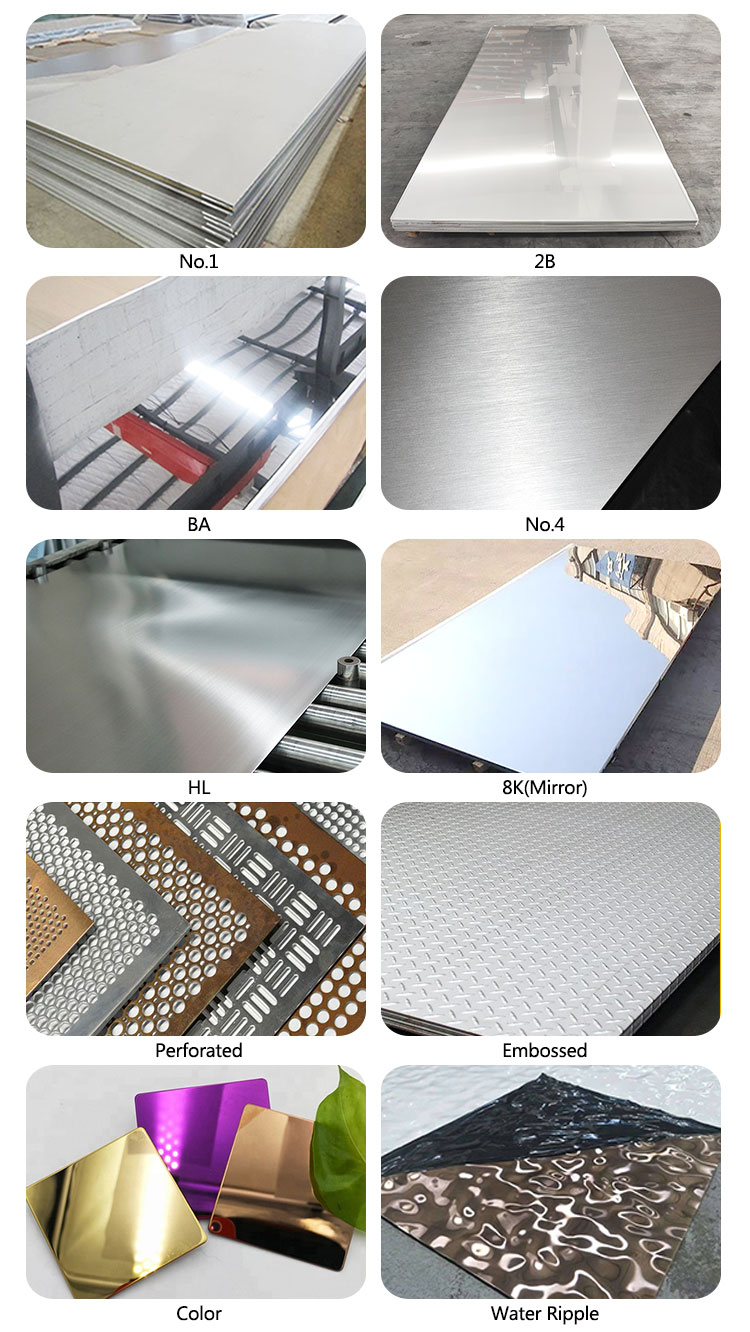

Surface: BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, polished outside, polished inside and outside

Stock: 8000 Ton/Month

PVC: 0.08 mm black/white PVC, Double blue PE, 0.1 mm laser PVC

Contact us: +86 13373795593

Duplex 2205 ((UNS S31803/UNS S32205/1.4462) is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. It is the most widely used duplex stainless steel grade and is characterized by high yield strength, double that of the standard austenitic stainless steel grades. It also demonstrates good fatigue strength, as well as outstanding resistance to stress corrosion cracking, crevice, pitting, erosion, and general corrosion in severe environments.

| Product | Duplex 2205 (UNS S31803/UNS S32205/1.4462) Sheet |

| Surface Finish | BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

| Technique | Hot Rolled / Cold Rolled |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

| Width | 500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

| Length | 500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

| Thickness | 0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

| Material | 201, 202 301, 302, 303, 303F, 303Cu, 304, 304L, 304H, 304F, 314 321, 316, 316L, 316Ti, 316F, 316LTi 309S, 310, 310S, 904L 409, 410, 416, 420, 430, 430F, 431, 436, 439, 441 317, 317L, 347H, 329, 630, 631, 17-4PH 2205, 2507, 2304, HASTELLOYC-276, C-22, C-2000, MONEL400, 254SMO, 253MA, Inconel1600, Inconel1625 Incoloy800, Incoloy800H, Incoloy825, Incoloy800HT GH3030, GH3039, GH2747 |

| Color | Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

| Stock Dimension | Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request Hot Rolled: 3.0-16.0mm*1250*2500mm/ 1500*3000mm/ 1500*6000mm/ 1800*6000mm/ 2000*6000mm, or as your request Thick Sheet: 6.0mm-80mm*width*length, as your request Mirror: 0.4-1.5mm*1000*2000mm/ 1219*2438mm and other customize size workable Hairline: 0.4-1.5mm*1000*2000mm/ 1219*2438mm and other customize size workable Color Coating: 0.4-1.5mm*1000*2000mm/ 1219*2438mm and other customize size workable Sandblasting: 0.4-1.5mm*1000*2000mm/ 1219*2438mm and other customize size workable |

| Service | OEM, Customized processing service, Customized fabrication by drawings |

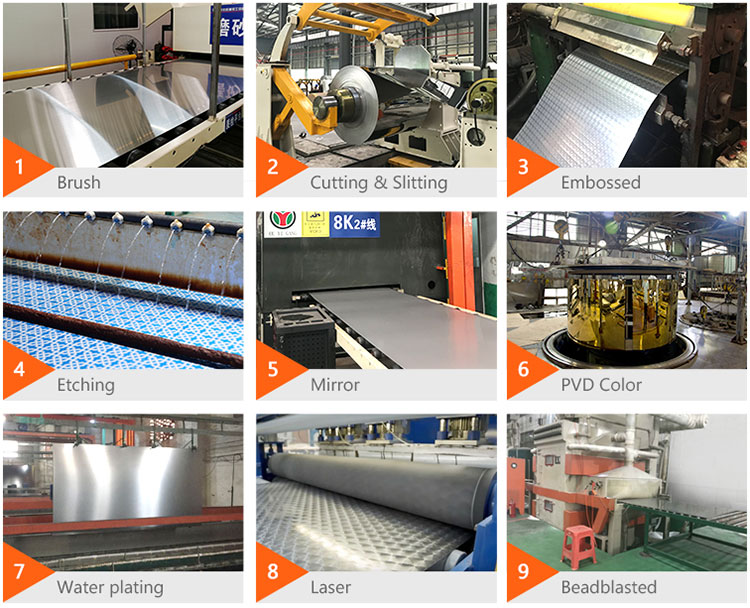

| Processing Type | Cutting, Bending, Stamping, Welding, CNC machining |

| Cutting Type | Laser cutting; Water-jet cutting; Flame cutting |

| Protection | 1. Inter paper available 2. PVC protecting film available |

| Application | Costruction Industry/ Kichten Products/ Fabrication Industry/ Home Decoration |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 2205 | 0.03 max | 2 max | 1.0 max | 0.03 max | 0.02 max | 21.0 – 23.0 | 2.5 – 3.5 | 4.5 – 6.5 | 0.08~0.2 |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 2205 | 8.0 g/cm3 | 1400 °C (2550 °F) | 90 | 65 | 25% |

1. ASTM/ASME: A240 UNS S32205/S31803

2.EURONORM: 1.4462 X2CrNiMoN 22.5.3

3.AFNOR: Z3 CrNi 22.05 AZ

4.DIN: W.Nr 1.4462

1.Corrosion Resistance: 2205 stainless stands-up excellently in a range of atmospheric environments even when exposed to corrosive elements, specifically to sea water.

2.Heat Resistance: Generally, 2205 is not suitable for use at temperatures above 300°C as it suffers from precipitation of brittle micro-constituents.

3.Avoid temperatures below -50°C because of its ductile-to-brittle-transition.

4.Easy to weld with excellent weldability.

5.The high strength of 2205 also makes bending and forming more difficult.

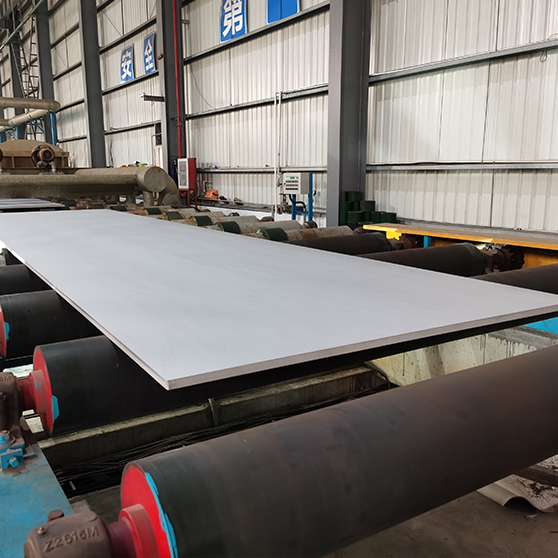

We have imported equipment and professional engineers, so that the surface of each our stainless steel plate is far higher than customer expectations.

| Surface | Characteristic | Processing Technology |

| N0.1 | Original | Pickled after hot rolling |

| 2D | Blunt | Hot rolling + annealing shot peening pickling + cold rolling + annealing pickling |

| 2B | Blurred | Hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + tempering rolling |

| N0.3 | Matte | Polishing and tempering rolling with 100-120 mesh abrasive materials |

| N0.4 | Matte | Polishing and tempering rolling with 150-180 mesh abrasive material |

| NO.240 | Matte | Polishing and tempering rolling with 240 mesh abrasive materials |

| NO.320 | Matte | Polishing and tempering rolling with 320 mesh abrasive materials |

| NO.400 | Matte | Polishing and tempering rolling with 400 mesh abrasive materials |

| HL | Brushed | Grind the surface of the steel belt with an appropriate grinding grain size to make it show a certain longitudinal texture |

| BA | Bright | The surface is annealed and shows high reflectivity |

| 6K | Mirror | Rough grinding and polishing |

| 8K | Mirror | Fine grinding and polishing |

We have imported equipment, 20,000 tons of inventory, professional masters, and a clean environment. Customer satisfaction is the basis of our service. If you need stainless steel materials, please contact our professional sales as soon as possible. They will give you the fastest. We make the most professional and reasonable quotation at the speed of our company, and look forward to our long-term cooperation as soon as possible.

We have all kinds of board production equipment, you can meet your various needs

1. Wide Specifications Range;

2. Pure steel chemical composition;

3. Outstanding mechanical properties;

4. Good performance after welding;

5. Good shape and high precision;

6. Excellent corrosion-resistant and long service life.

Stainless Steel Sheet are widely used in below fields:

1. Chemical processing, transport and storage – pressure vessels, tanks, piping, and heat exchangers;

2.Oil and gas exploration and processing equipment – piping, tubing, and heat exchangers;

3.Marine and other high chloride environments;

4.Pulp and paper industry – digesters, bleaching equipment, and stock-handling systems;

5.Cargo tanks for ships and trucks;

6.Food processing equipment;

7.Biofuels plants.

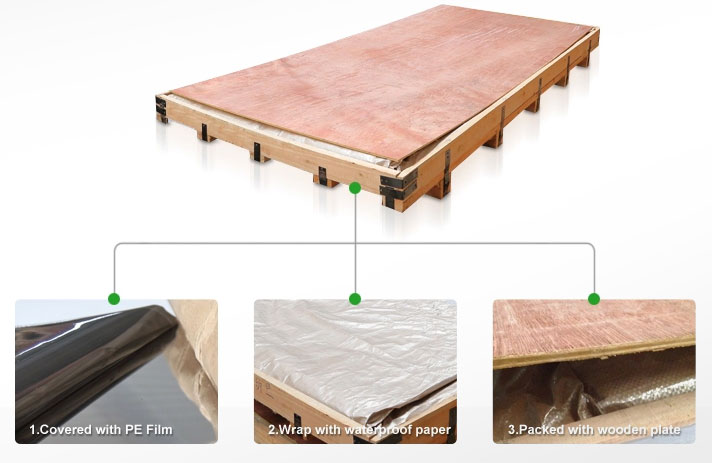

1. Sheets covered with wooden plate for protection in transportation;

2. All sheets will be loaded in strong wooden packages;

3. Every cartons loaded with good shoring and strengthening;

4. Take container loading pictures and seal the container;

5. Transportation speed is quick. And keep customer each step informed.