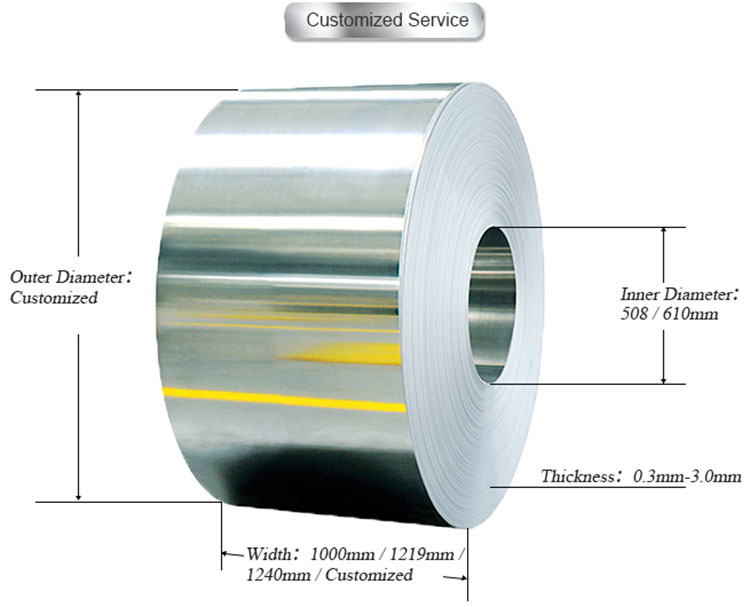

Thickness: 0.1~16mm,or as customer’s requirements

Width: 10-2000mm or as customer’s requirements

Material: Material: 201 304 321 316 316L 430, etc

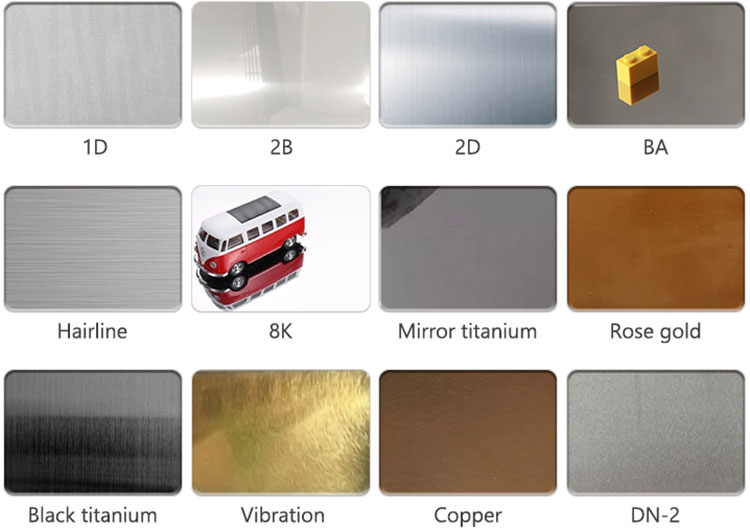

Surface: N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etc

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc

Certification: ISO, SGS, BV

Stock: 5000 Ton/Month

Quality control: Third Part Inspection is acceptable.

Delivery Time: Within 3 days for our stock size,15-20days for our production

Contact us: +86 13373795593

Alloy 310 (UNS S31000) is an austenitic stainless steel developed for use in high temperature corrosion resistant applications. The alloy resists oxidation up to 2010oF (1100oC) under mildly cyclic conditions.

310S (UNS S31008) is the low carbon version of the alloy. It is utilized for ease of fabrication. 310H (UNS S31009) is a high carbon modification developed for enhanced creep resistance. In most instances the grain size and carbon content of the plate can meet both the 310S and 310H requirements.

Alloy 310 coils can be easily welded and processed by standard shop fabrication practices

| Product | 310S Stainless Steel Coil |

| Width | 10-2000mm or as customer's requirements |

| Thickness | 0.1~16mm,or as customer's requirements |

| Surface | N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etc |

| Material | 201, 202 301, 302, 303, 303F, 303Cu, 304, 304L, 304H, 304F, 314 321, 316, 316L, 316Ti, 316F, 316LTi, 309S, 310, 310S, 904L 409, 410, 416, 420, 430, 430F, 431, 436, 439, 441 317, 317L, 347H, 329, 630, 631, 17-4PH 2205, 2507, 2304, HASTELLOYC-276, C-22, C-2000, MONEL400, 254SMO, 253MA, Inconel1600, Inconel1625, Incoloy800, Incoloy800H, Incoloy825, Incoloy800HT GH3030, GH3039, GH2747 |

| Standards | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Certifications | ISO, SGS, BV |

| Packing | Industry standard packaging or according to client's requirement |

| Delivery time | Within 3 days for our stock size,15-20days for our production |

| Grade | C | Si | Mn | Cr | P | S | Ni | |

| 310S | min | - | - | - | 14 | - | - | 19 |

| max | 0.08 | 1.5 | 2 | 26 | 0.045 | 0.03 | 22 | |

| Grade | Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

| 310S | psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 35,000 | 245 | 80,000 | 550 | 45 | 217 Brinell | |

| Stainless Steel Coil/Sheet/Plate Information | ||||||||||

| Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | Application | |||||

| Main Dimension | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Hot Rolled | No.1 / 2E | 201/202/304 | 2.2-12.0 | √ | √ | √ | √ | √ | Petro-chemical industry,Tanks Construction material |

|

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | √ | √ | √ | √ | √ | √ | |

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | |||||

| Hairline | 201/304 | 0.22-3.0 | √ | √ | √ | √ | √ | |||

| Mirror | ||||||||||

| SB | 410S/430 | 0.25-2.0 | √ | √ | √ | √ | √ | |||

| BA | 201/304 | 0.2--1.8 | √ | √ | √ | √ | ||||

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | |||||

| 2BA | √ | √ | √ | √ | ||||||

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. |

| BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. |

| NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. |

| HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. |

| 6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator's wall doors, counters,sculptur |

We have strict quality control before our products go out, And we have all kinds of board production equipment, you can meet your various needs.

1. Wide Specifications Range;

2. Pure steel chemical composition;

3. Outstanding mechanical properties;

4. Good performance after welding;

5. Good shape and high precision;

6. Excellent corrosion-resistant and long service life.

Stainless steel coils are widely used in below fields:

1. Used in industrial, chemical equipment;

2. Used in life stainless steel items;

3. Building materials, architectural decoration;

4. Storage tanks used for appliances and kitchen equipment.

We provide ordinary packaging for free, and can also customize packaging and logo according to buyers. Our common package are as below:

1. Coils covered with wooden plate for protection in transportation;

2. All coils will be loaded in strong wooden packages;

3. Every cartons loaded with good shoring and strengthening;

4. Take container loading pictures and seal the container;

5. Transportation speed is quick. And keep customer each step informed.